Benefits and challenges of 3D printing in construction

Augmented Reality – The future of the construction industry

January 20, 2022

Green Cement- The future of Sustainable Construction

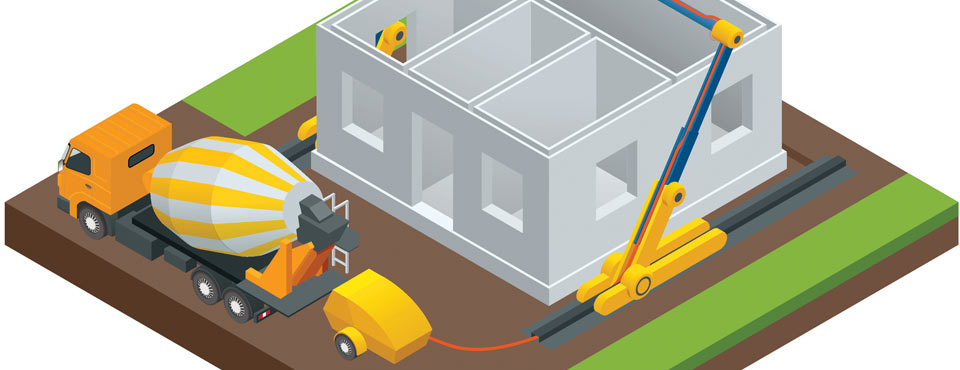

March 2, 20223D printing technology has created a lot of buzz in the past decade. This disruptive innovation has changed the course of almost all industries. From medical to automobiles, education to aerospace, this technology has proven its mettle. But it is a feasible leap for the construction industry too? Let us delve into the benefits and challenges of 3D printing in the construction industry.

But before that let’s understand what 3D printing technology means.

3D printing is a cutting-edge manufacturing process in which a CAD (computer-aided design and drafting) or BIM (Building Information Modelling) program tells the 3D printer what it needs, and the printer creates a real-life three-dimensional(3D) object by depositing materials layer by layer. In simple words, it is like giving the printer a precise design command and the printer would use the necessary materials to create the designated model.

Benefits of 3D printing in construction

Faster Speed of Construction

The biggest advantage of using a 3D printer in construction would be the speed with which the projects could be completed. Not only does it take much lesser time to build the structures, but it can also work 24 by 7. In recent years, 3 D printing has been successful in building a home from scratch in a matter of days. According to some reports, 3D printing could save about 60% of the time on jobsite.

Low waste construction

The construction industry is a major contributor to global waste production. But with 3D printing, this waste generation could be lowered by considerable numbers. A 3D printer uses the resources with precision, thus cutting down any wastage.

Reduced health and safety hazards

The construction industry is usually considered a risky business. Especially the concrete work can be hazardous to health. Using a 3D printer for these jobs could minimize the risks of injuries and fatalities. That’s one of the prime reasons to try this technology in the construction industry.

Increased accuracy

With 3D printing, construction companies can achieve a high level of accuracy in building concrete structures. In a 3D printing model, instead of pouring concrete into traditional molds, 3DCP (3D concrete printing) pours materials in layers using a computerized process. This increases the quality and precision of the structures.

High level of design freedom

3D printing allows architects and designers to build complex designs that are otherwise labor intensive and expensive. With 3D concrete printing, one can easily achieve any shape with ease. This allows the designers to be more creative in the construction space.

Tailored Constructions

In traditional methods of construction that use mold and cutting, customization was a very time-consuming and labor-intensive process. In addition to that, there was no guarantee of durability of such constructions that are created on an experimental basis. But 3D printing ensures enhanced structural integrity. It also allows the alteration of certain parts to fit certain requirements.

Challenges of 3D printing

Cost

Cost is one of the prime barriers that’s obstructing the widespread use of 3D printing in construction. The high cost of owning or renting this equipment and getting these large 3D printers to the worksite is a major hurdle. In addition to that, the cost of materials and maintenance is a burden that not many constructors are eager to bear.

Skills

Another major setback is the lack of skilled labor in the construction industry. To operate the 3D printer, one needs to be trained to design computer models, operate the equipment, and service it when needed. 3D printing requires a specific skill set that makes it both costly and hard to find.

Costly mistakes

While 3D printing does minimize the chances of human errs. It could also end up producing expensive and rapid mistakes if the projects are not overseen with expertise.

Acceptance

One of the biggest problems in the launch of new technology is the hesitation in acceptance. Would people agree to live in a house built with 3D printing technology? When it comes to construction, people prefer sticking to traditional methods because of a common misconception that technology makes construction cheaper and weaker.

The future of 3D printing in the construction realm

Despite the challenges, experts are optimistic that 3D printing would be the future of construction. The current challenges posed are common barriers that any new technology faces when launched in the market. They are most likely to resolve over time with testimonies of success. The equipment cost will come down with widespread acceptance, more people would be trained to operate it and the benefits would outweigh the challenges by far.

Thus, we can say that 3D printing technology is not a flickering trend but the future of the construction industry.